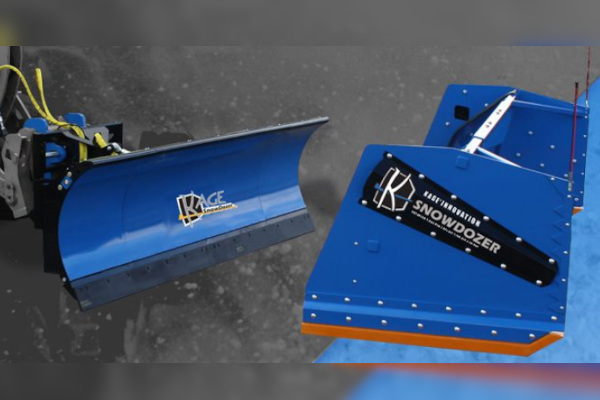

Kage SnowDozer

Features

SYSTEM

Combining Snow Plowing with Snow Pushing

The KAGE SnowDozer system combines snow plowing and snow pushing into one wheel loader machine, and one operator. The simple advantages angle plowing and snow pushing are brought together seamlessly by being able to reliably switch between the two from the cab, in seconds.

A regular snow pusher box is less productive without having another piece of equipment along to do back dragging, scraping, and general cleanup. Not to mention that it will leave trails on both sides once it becomes full of snow.

The KAGE SnowDozer System can angle and ‘swoop’ out corners – even with the containment box attached. The SnowKAGE box comes completely off of the plow simply by retracting it hydro locking pins. Angle plow with a snow blade that oscillates to maintain contact with the surface. Adjust the attack angle of the blade to customize the roll of the snow as its scraped as well as how far the blade will through the snow.

Convert the SnowDozer into a large box plow by locking into the side panels – and push large quantities of snow in a hurry!

The KAGE system is great for close proximity cleanup, as well as straight snow stacking and hugging corners. Because the plow and box can angle and separate, the operator can fit into smaller areas than before, and when it’s time to just push, you still have the weight and horsepower needed to push mountains of snow!

The applications for the KAGE SnowDozer system combined with the brute force of large wheel loaders are virtually endless. Imagine the profitability gained by replacing a pusher and a pickup truck with one KAGE System. Your sites can look better, faster, with less equipment and manpower. That is the KAGE Advantage.

The Blade

Modular Moldboard(s)

The snow blade is the backbone of the SnowDozer System. With that in mind, we build each moldboard as if it has to go into battle.

The modular design of the SnowDozer moldboard allows you to customize just the right size plow for the job – without the wait of an entirely custom plow!

High-strength, low alloy grade 50 steel is the standard for the moldboard skin showing that we care about the materials we use. Not only does that increase tensile strength over mild steel but helps reduce the effects of corrosion.

Baked on powder coat and primer at 400+ degrees safeguards all of the steel components and keeps the blade looking great for years. The standard blue and black two-tone finish that is so unique to KAGE is a long lasting, quality product by KAGE Innovation®.

Trip Edge

The SnowDozer blade has split trip edges which safeguard from damage when encountering hidden obstacles. Trip edges trip back to clear obstacles such as curbs, and manhole covers. Due to the length of the SnowDozer moldboard, the trip edges are split – meaning one section of the cutting edge can trip independently from another. This helps prevent the cutting edge from twisting and damaging both the cutting edge and the moldboard.

The trip edges are a crucial feature for efficient plowing. You can’t tip-toe around things that you cannot see, that takes too much time. Let the trip edge be your ‘whiskers’ letting you know what is out there!

Both sections of the trip edge have 3/4 x 8” High Carbon steel cutting edges standard. KAGE sectional cutting edge – the AdvantEdge system is optional.

The standard cutting edges are common to the highway plow market, and the hole spacing is referred to as a “Standard Highway Punch”, so replacements are available most anywhere it snows; no need to stock custom edges or hardware for replacements!

The trip edge action is powered by compression spring packs. The springs keep the edge from false tripping while pushing, meaning you can scrape and push without tripping unnecessarily.

Hydraulic System

The hydraulic system for the snow blade powers the plow left and right for up to 34-degree angle plowing using two 3” bore x 1.5” rod hydraulic cylinders.

If you are using it in combination with the SnowKAGE, it locks the box onto the plow hydraulically.

We, too, absolutely dread that ‘midnight maintenance’ so we had that in mind when we put this hydraulic system together. This resulted in standard preventative stuff like abrasion resistant cloth hose covering on all hoses, and a 2500 psi crossover relief valve standard.

The electric diverter valve is standard equipment with the system, which enables machines with only one auxiliary function to operate the hydro lock pins to lock the SnowKAGE on as well as the angle function of the plow. Just the flick of a switch is all you need to switch power from the angle cylinders to the lock pins.

You won’t have to think twice about the durability of the Deutsch® plugs, heavy duty 5/8” O.D. ‘trailer cable’, strain relief cord grip, or lighted solenoids that all make up this expert setup.

The standard valve operates on 24VDC, a 12VDC option is available.

Angle Cylinders

Heavy duty 3″ Bore x 1.5″ Cylinders power the plow left and right 34 degrees.

Heavy duty knuckles keep the cylinders from binding as the plow oscillates.

Wire Harness

The provided wire harness runs up into the cab, and has a Deutsch plug midstream to quickly disconnect the plow from the machine.

Alternatively, if you are running Cat brand machines, the 8-pin wire harness will plug directly into the auxiliary power supply and uses the OEM in cab auxiliary switch.

Floating Quick Attach

The quick attach that couples the carrier (machine) to the plow has float built right into the ears. The lower pivot points rotate on 2 x 2″ diameter 1018 cold rolled pins, while the upper slots allow the plow to float up and down riding perfectly over humps and dropping into dips.

This floating system allows the operator to concentrate on driving, and not so much on the tilt or level that the plow is sitting at. Don’t worry, whenever you want positive down pressure, simply tip the attachment forward until the quick attach meets the end of the slots, and pushes into the plow frame. (see the options tab for a list of available quick attaches)

Plow Oscillation

The SnowDozer front end loader plow oscillates side to side to keep the cutting edges on the plowing surface at all times. The oscillation happens directly on the moldboard itself, so as the plow is hydraulically angled, the oscillation still operates as usual.

The bottom line is that no matter the plow angle, the oscillation will still perform as it should.

Another notable feature that is unique to the SnowDozer is our new oscillate control system, or OCS. This system uses two factory-pressurized (10 PSI) hydraulic rams to level the plow when it is elevated – for example during transport.

Throw Pitch

The 48” tall moldboard can be manually trimmed to adjust the snow throwing pitch, and attack angle of the cutting edge.

Highway Punch Cutting Edges

The SnowDozer comes equipped with 8″ x 3/4″ thick 1084 High Carbon steel cutting edges. The cutting edges comply to the standard ‘Highway Punch’ mounting pattern, so no need for custom cutting edges. We really strive to make it easy for you, and if it’s easier for you to source cutting edges locally, do that. Otherwise you can purchase them directly from the factory, or one of our authorized dealers!

The Box

The SNOWKAGE Box

The SnowKAGE box is the genius behind the SnowDozer System. So simple yet so intuitive. It stands alone when not in use, but mates perfectly to the snow blade when needed in order to push huge amounts of snow out of the way.

Tough Supports

Tough, triangulated supports mean that you can push this to the extreme with no breakdowns. Kage SnowDozer supports are made from high quality, durable steel and are designed to endure the heaviest snow without failing.

Keep in mind that this plow is also designed to handle the down pressure of payloaders weighing up to 50,000 lbs. When tackling jobs big enough to warrant this beast of a plow, you can’t afford to spend time fixing broken supports.

Polyurethane Skids

The 2” thick polyurethane skids are gentle on curbs and other surfaces prone to damage. The steel formed parts that hold the skid are slotted for adjustment as the cutting edge of the plow becomes worn.

The 10” wide, ½” thick conveyor belt “snow catch” contours to the radius of the moldboard keeping the snow sealed within.

Hydro Lock Pins

The Hydro Lock Pins drive out from each end of the plow hydraulically to engage the openings in the SnowKAGE.

Each opening is enlarged so that the SnowKage Box can float up and down, and tilt forward and backwards. This ensures that the SnowKage floats independently from the plow, and the cutting edges of the plow are in constant contact with the plowing surface!

You don’t have to worry about getting the perfect pitch adjustment – just drop and go!

Options

Wheel Loader Attachments

Quick Attaches

ss-loader-hitch-picThe wheel loader hitch can accommodate most quick attaches found on wheel loaders and tractor loader backhoes.

The pivot frame of the plow remains the same, and the quick attach, particular to your make / model of machine merely pins on with 4, 2-inch pins.

Look closely and you will see that the blade will float up and down for uneven terrain. Down pressure? Sure, just ‘dump’ the quick attach with the curl function and it will bottom out, creating down pressure for back dragging or scraping ice!

| Make / Model | KAGE Part Number |

| JRB ® 416 | JRB416 |

| JRB ® 418 | JRB418 |

| CAT ® IT28 | CATIT28F-K |

| JCB 514 | JCB514 |

| JRB® 418 | JRB418 |

| CAT® IT38 | CATIT38F-K |

| CAT® FUSION® | CATFUSION |

| JOHN DEERE® WORKSITEPRO® | JDWKSP |

| HYUNDAI® | HL740TM |

| ACS® | CALL |

| VOLVO® | 356-1 |

| TEREX | TERSKI863 |

3 Point Hitch

SS-3-POINT-HITCHThe 3-point hitch provides a compact attachment, and full range of motion while keeping the plow as close to the machine as possible. Universal to any CAT II 3-point hitch, it can be used in combination with one of our Kage Tractor Undercarriages, or any other brand.

Screw-Type Couplers

Cat screw-type couplers are optional to replace the standard 1/2″ Body Flat Faced ISO 16028 couplers.

12VDC Coils

Optionally choose the 12VDC coils instead of the standard 24VDC coils, if your machine has a 12VDC system.

Specifications

The Blade SD

| For Machines Weighing 25,000 - 50,000 lbs | BP12 |

| Machine Size Rec. | 25K-50K |

| Angle | 34° |

| Blade Width | 12′ |

| Blade Width at Full Angle | 130″ |

| Oscillation Each End (Degrees/Inches) | 12° |

| Moldboard Gauge/Steel Grade | 10 ga. / Grade 50 |

| Trip Springs (Compression) | 6 |

| Cutting Edge (High Carbon) | 3/4″ x 8″ x 6′ (2) |

| Pivot Frame Length for Loader Attachment | 48″ |

| Weight | |

| Cylinders | 3″ Bore 1 1/2″ Rod (2) |

| Blade Height | 48″ |

| For Machines Weighing 25,000 - 50,000 lbs | BP14 |

| Machine Size Rec. | 25-50K |

| Angle | 34° |

| Blade Width | 14′ |

| Blade Width at Full Angle | 150.06″ |

| Oscillation Each End (Degrees/Inches) | 12° |

| Moldboard Gauge/Steel Grade | 10 ga. / Grade 50 |

| Trip Springs (Compression) | 6 |

| Cutting Edge (High Carbon) | 3/4″ x 8″ x 7′ (2) |

| Pivot Frame Length for Loader Attachment | 48″ |

| Weight | |

| Cylinders | 3″ Bore 1 1/2″ Rod (2) |

| Blade Height | 48″ |

| For Machines Weighing 25,000 - 50,000 lbs | BP16 |

| Machine Size Rec. | 25-50K |

| Angle | 34° |

| Blade Width | 16′ |

| Blade Width at Full Angle | 170″ |

| Oscillation Each End (Degrees/Inches) | 12° |

| Moldboard Gauge/Steel Grade | 10 ga. / Grade 50 |

| Trip Springs (Compression) | 8 |

| Cutting Edge (High Carbon) | 3/4″ x 8″ x 8′ (2) |

| Pivot Frame Length for Loader Attachment | 48″ |

| Weight | |

| Cylinders | 3″ Bore 1 1/2″ Rod (2) |

| Blade Height | 48″ |

| For Machines Weighing 25,000 - 50,000 lbs | BP18 |

| Machine Size Rec. | 25-50K |

| Angle | 34° |

| Blade Width | 18′ |

| Blade Width at Full Angle | 225.25″ |

| Oscillation Each End (Degrees/Inches) | 12° |

| Moldboard Gauge/Steel Grade | 10 ga. / Grade 50 |

| Trip Springs (Compression) | 8 |

| Cutting Edge (High Carbon) | 3/4″ x 8″ x 9′ (2) |

| Pivot Frame Length for Loader Attachment | 48″ |

| Weight | |

| Cylinders | 3″ Bore 1 1/2″ Rod (2) |

| Blade Height | 48″ |

| For Machines Weighing 25,000 - 50,000 lbs | BP20 |

| Machine Size Rec. | 25-50K |

| Angle | 34° |

| Blade Width | 20′ |

| Blade Width at Full Angle | 209.75 |

| Oscillation Each End (Degrees/Inches) | 12° |

| Moldboard Gauge/Steel Grade | 10 ga. / Grade 50 |

| Trip Springs (Compression) | 12 |

| Cutting Edge (High Carbon) | 3/4″ x 8″ x 9′ (2) |

| Pivot Frame Length for Loader Attachment | 48″ |

| Weight | |

| Cylinders | 3″ Bore 1 1/2″ Rod (2) |

| Blade Height | 48″ |

The SNOWKAGE SD

| For Machines Weighing 25,000 - 50,000 lbs | BPSK12 |

| Machine Size Rec. | 25-50K |

| Height of Box | 41″ |

| Overall Width | 155.12″ |

| Overall Width at Full Angle | 165.5″ |

| Poly Skids | 2″ x 10″ x 42″ |

| Weight (Blade and Box) |

| For Machines Weighing 25,000 - 50,000 lbs | BPSK14 |

| Machine Size Rec. | 25-50K |

| Height of Box | 41″ |

| Overall Width | 179.12″ |

| Overall Width at Full Angle | 185.37″ |

| Poly Skids | 3.5″ x 6.75″ x 66″ |

| Weight (Blade and Box) |

| For Machines Weighing 25,000 - 50,000 lbs | BPSK16 |

| Machine Size Rec. | 25-50K |

| Height of Box | 41″ |

| Overall Width | 203 1/8 |

| Overall Width at Full Angle | 205.31″ |

| Poly Skids | 3.5″ x 6.75″ x 66″ |

| Weight (Blade and KAGE) |

| For Machines Weighing 25,000 - 50,000 lbs | BPSK18 |

| Machine Size Rec. | 25-50K |

| Height of Box | 41″ |

| Overall Width | 227 1/8 |

| Overall Width at Full Angle | 225.25″ |

| Poly Skids | 3.5″ x 6.75″ x 66″ |

| Weight (Blade and KAGE) |

| For Machines Weighing 25,000 - 50,000 lbs | BPSK20 |

| Machine Size Rec. | 25-50K |

| Height of Box | 41″ |

| Overall Width | 251.12 |

| Overall Width at Full Angle | 245.12 |

| Poly Skids | 3.5″ x 6.75″ x 66″ |

| Weight (Blade and KAGE) |

Available Quick Attaches

| Make / Model | Number |

| JRB 416 | JRB416 |

| JRB 418 | JRB418 |

| CAT IT28 | CATIT28F-K |

| JCB 514 | JCB514 |

| JRB 418 | JRB418 |

| CAT IT38 | CATIT38F-K |

| CAT FUSION | CATFUSION |

| JOHN DEERE WORKSITEPRO | JDWKSP |

| HYUNDAI | HL740TM |

| ACS | CALL |

| VOLVO | 356-1 |

| TEREX | TERSKI863 |